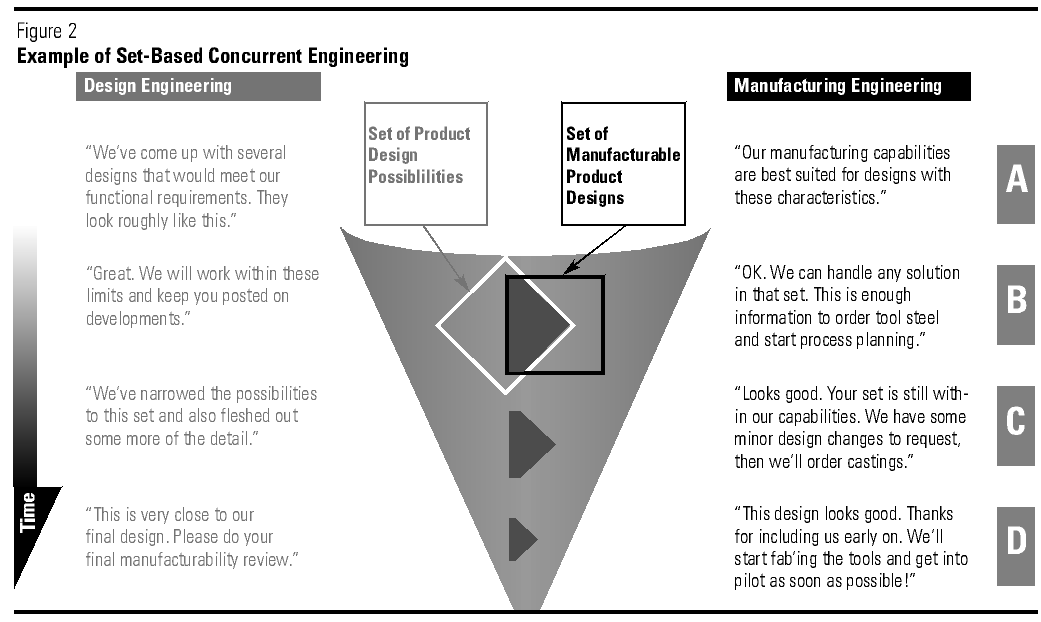

Concurrent Engineering Example

- This paper reviews concurrent engineering from the viewpoint of engineering design research., Concurrent engineering aims at eliminating unnecessary changes and redesigns from a product development process, and at achieving better product quality.

- The concurrent engineering method is still a relatively new design management system, but has had the opportunity to mature in recent years to become a well-defined systems approach towards optimizing engineering design cycles.

Concurrent engineering (CE) is an approach to new product development, which differs from the traditional approach because new product development tasks are performed simultaneously, instead of in a.

Concurrent engineering, also called simultaneous engineering, is a process for designing and creating products in which project workers carry out each stage at the same time, rather than one after the other. For instance, the design team for an auto manufacturer can work on the shape of a new car while technicians test its aerodynamics in the wind tunnel. Although the initial attempts at concurrent engineering can be challenging, the practices involved deliver several competitive advantages.

Faster Time To Market

A major advantage that concurrent engineering offers is that it allows companies to deliver their products to market in a much shorter time frame. When product development stages run consecutively, the workers on prototyping stage must wait until those on design phase have completed their tasks, those on testing phase must wait until those in prototyping phase are finished, and so on. All of this waiting can delay product releases. Concurrent engineering allows workers on several stages to work simultaneously, shortening the time to market.

Enhanced Quality

Concurrent Engineering Is A Good Example Of Good Use Of

Concurrent engineering practices also enable workers and managers to discover any production issues earlier in the process, which leads to a higher-quality product. These practices also reduce design revisions, unworkable prototypes and excessive testing to arrive at the highest-quality product in the shortest time. In the auto manufacturer example, any issues involving the aerodynamics of the car are uncovered earlier in the process by the testing team, which allows the design and prototyping teams to work toward solving the problem.

Lower Development Costs

The bulk of a company's costs associated with creating a new product involve the design and development processes. Managers can use concurrent engineering as a powerful tool for reducing those early development costs. Since concurrent engineering practices decrease the time spent in the design and development phases, companies can deliver a product faster, better and cheaper than their competitors. In the auto manufacturer example, concurrent engineering practices allow the design, prototyping and testing teams to produce a factory-ready car design in much less time and at a lower cost to the company.

Increased Productivity

Concurrent Engineering Pdf

While consecutive engineering requires that workers on a later stage wait for those in earlier stages, concurrent engineering allows workers the opportunity to be productive immediately and throughout the process. This process allows workers to focus on the project as a whole, rather than focus solely on their area of specialty. In the auto manufacturer example, the design, prototyping and testing teams all work together on the same problem at the same time to find the best solution.

- Klaus Tiedge/Blend Images/Getty Images